- Inbound containers are inspected for leaks and structural soundness.

- Outlines are made around the areas that need to be restored. SF does not use cheap epoxy to seal to fix leaks like some short cut outfits. We know any hole is an invitation to oxidation so we use super tough core-ten steel like the original container is made of or a matching metal in the case of refrigerated containers using stainless steel and aluminum.

- Then our container engineers cut out the bad part and expertly weld in the matching replacement part to watertight strength.

- Doors alignment and closing mechanisms are inspected for operation. These are re-aligned or replaced and lubricated as needed.

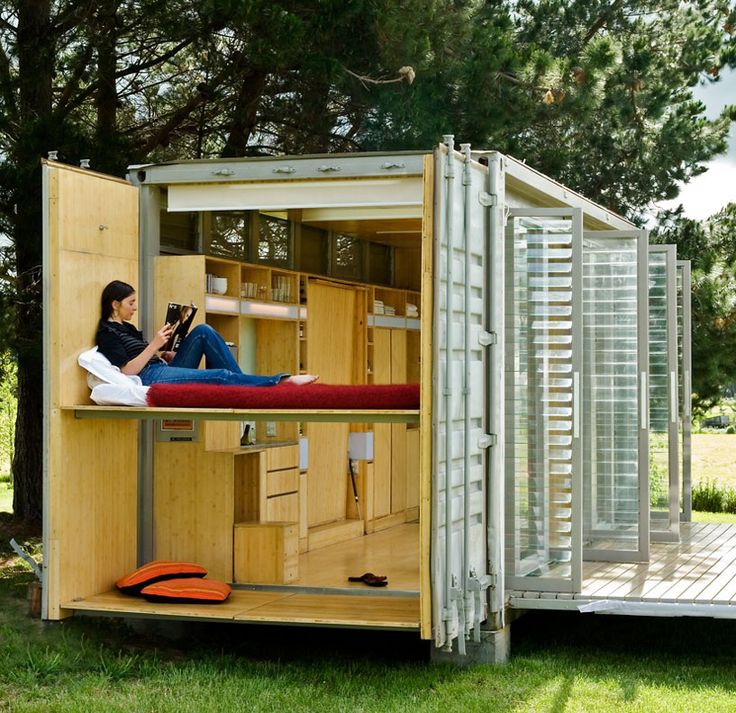

- If this is a custom order such as a specialized vandal proof lock being fitted or extra door cutout and door it is done at this juncture in the process.

- Then the shipping container is prepared and painted inside and out in your desired color(s). The specialized paint used prevents oxidation for years. A specialized epoxy roof coating that has substantial R value can be applied upon request.

- The recycled shipping container is then ready for delivery to your door on one of our fleet of trucks that are on the roads of Florida 6 days a week all day long.

- Delivery is super fast and easy as our specialized trucks tilt the container and it slides right off the back.

- Custom tamper cut resistant locking mechanism

- Custom Steel Man Doors

- Barn Doors

- Turbines for cooling

- Anything you can think of we can make